Reverse-Engineering

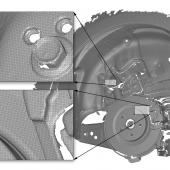

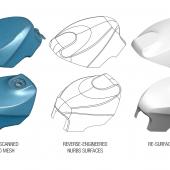

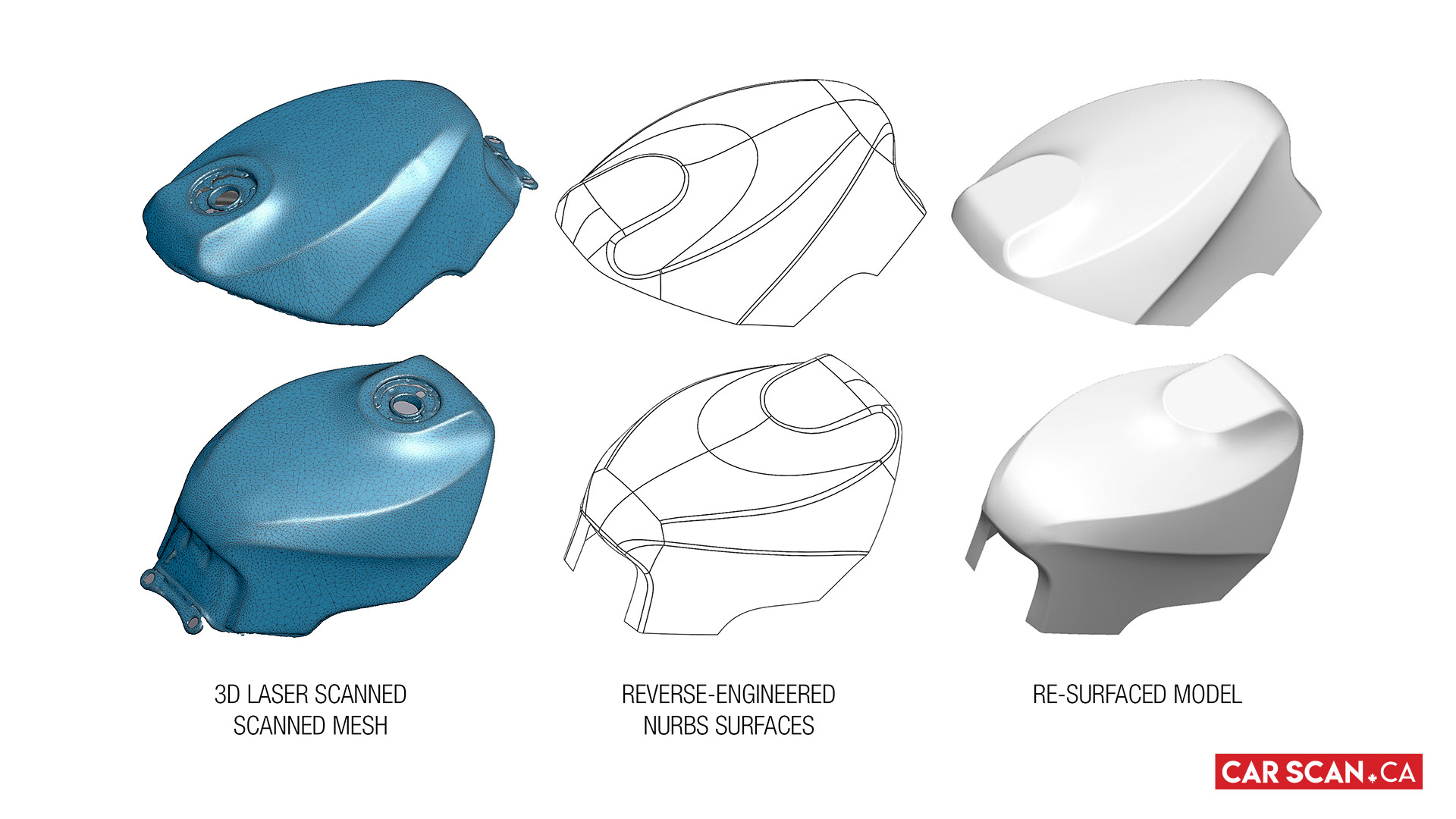

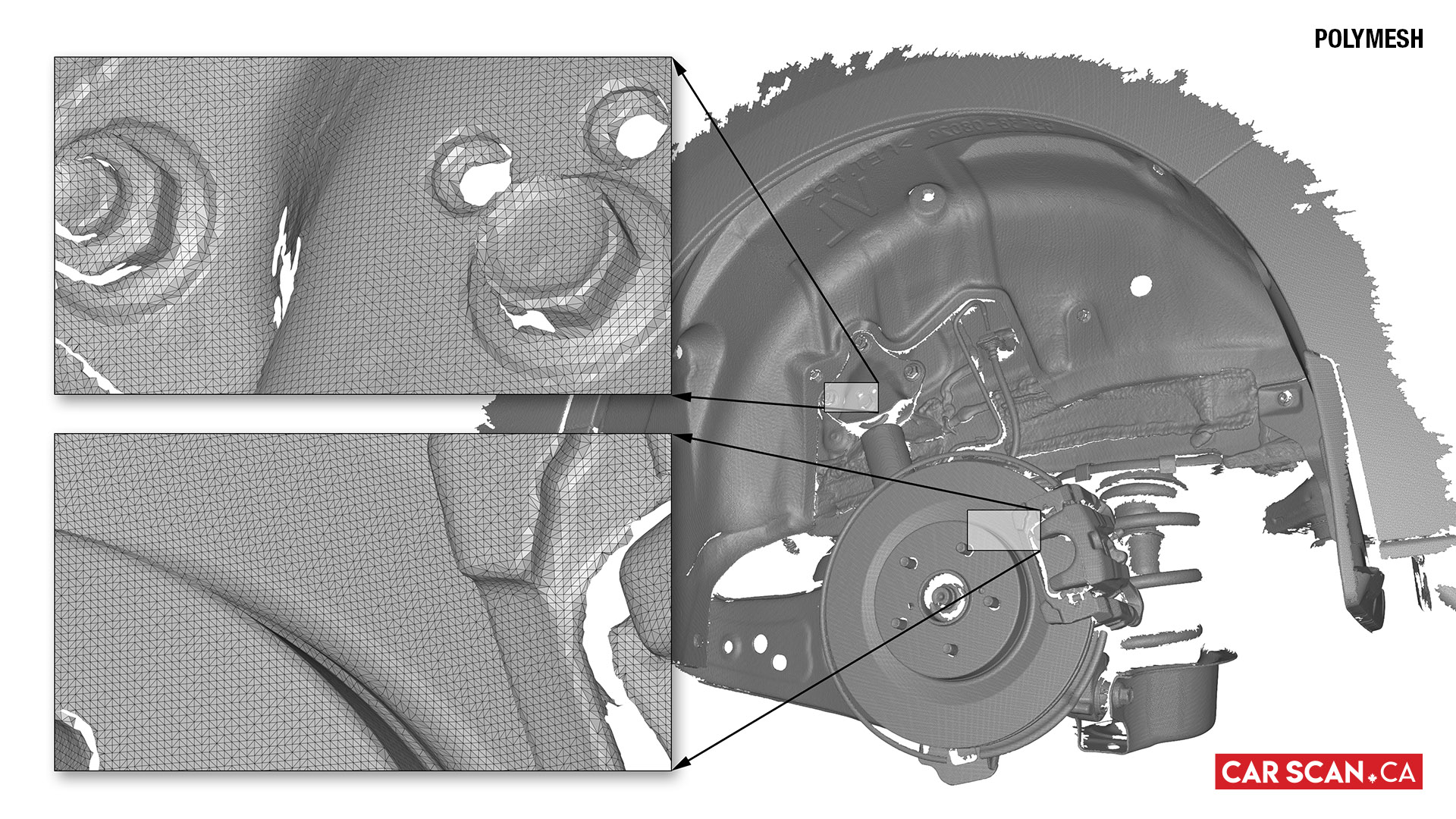

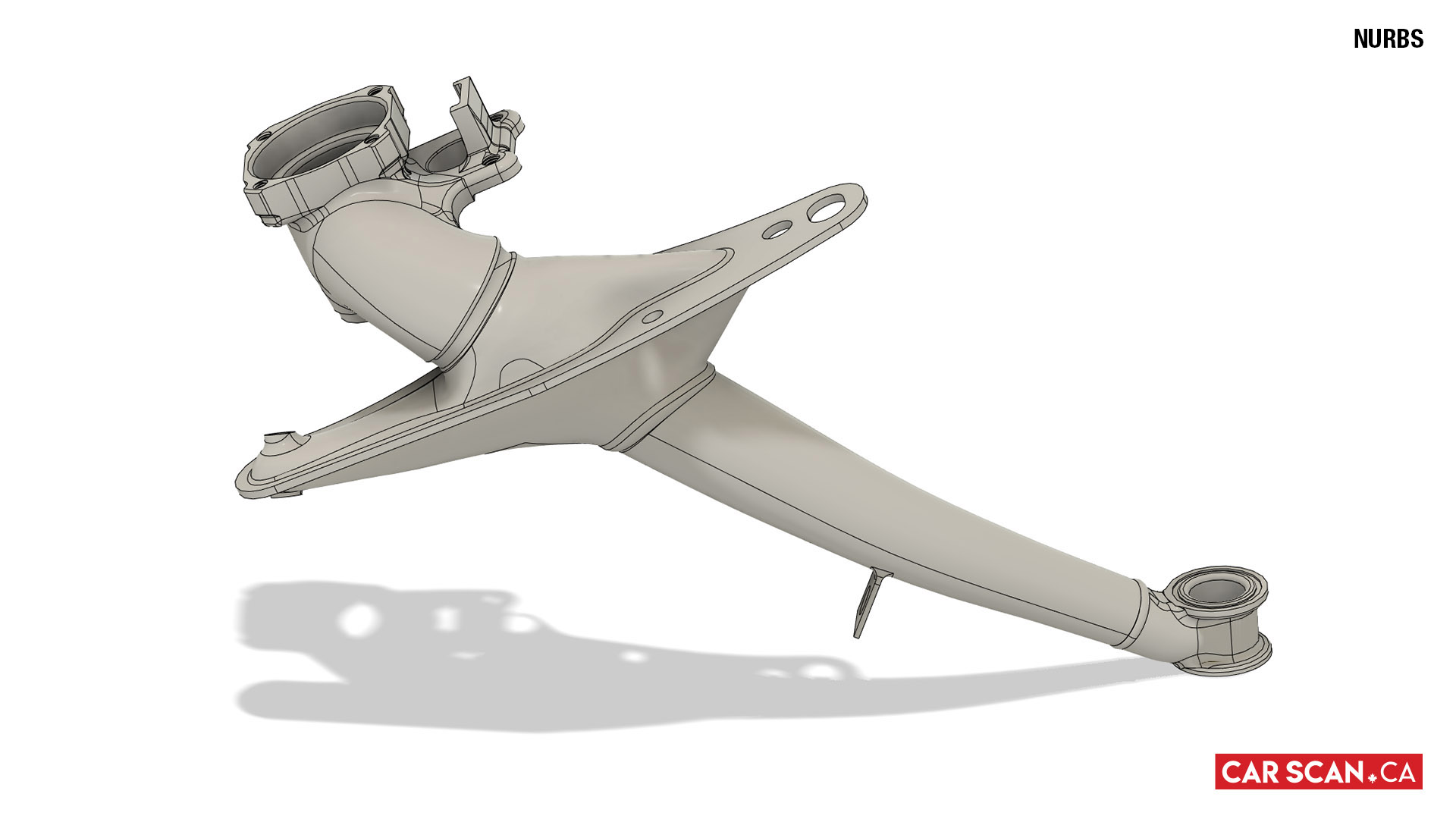

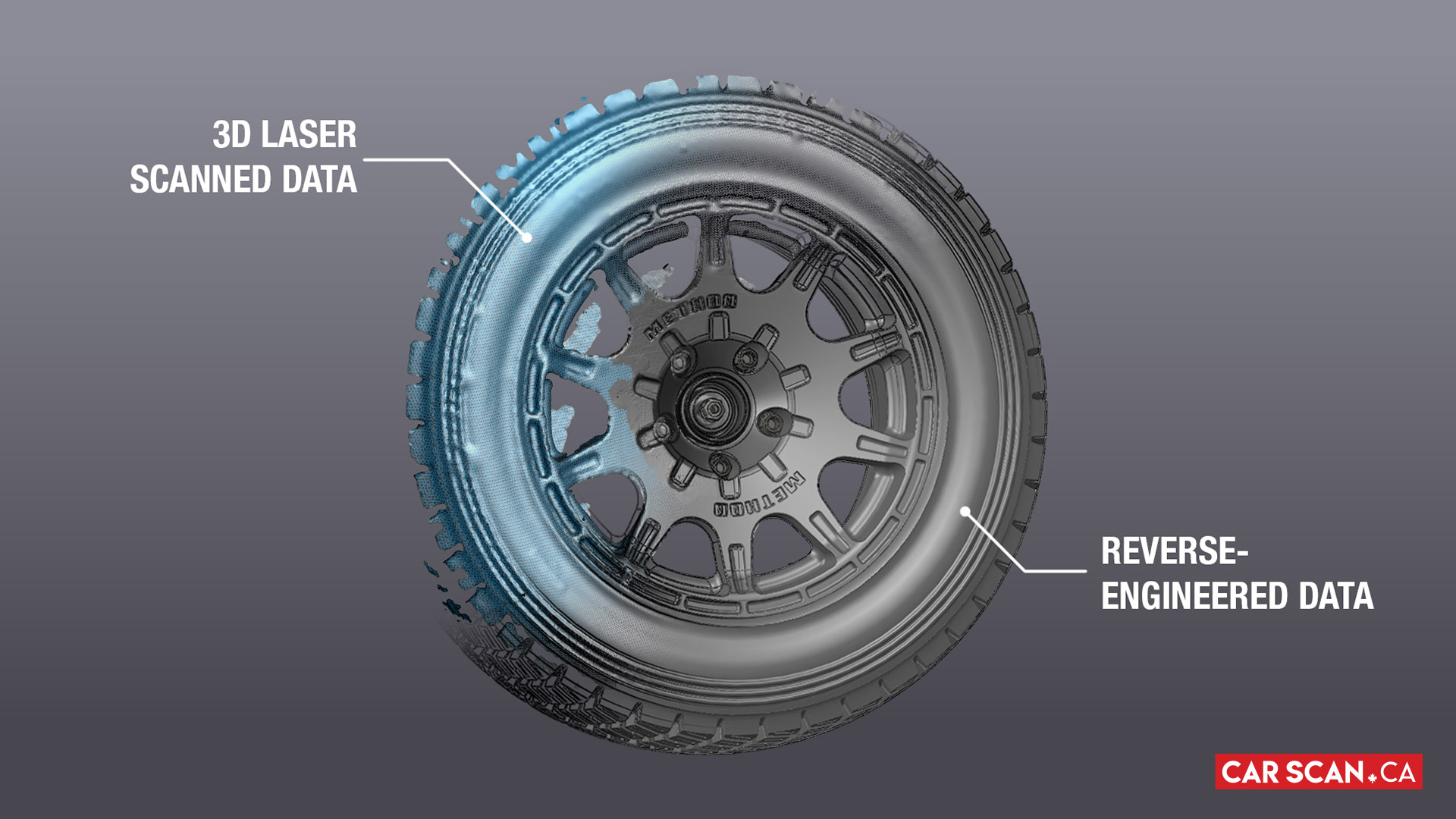

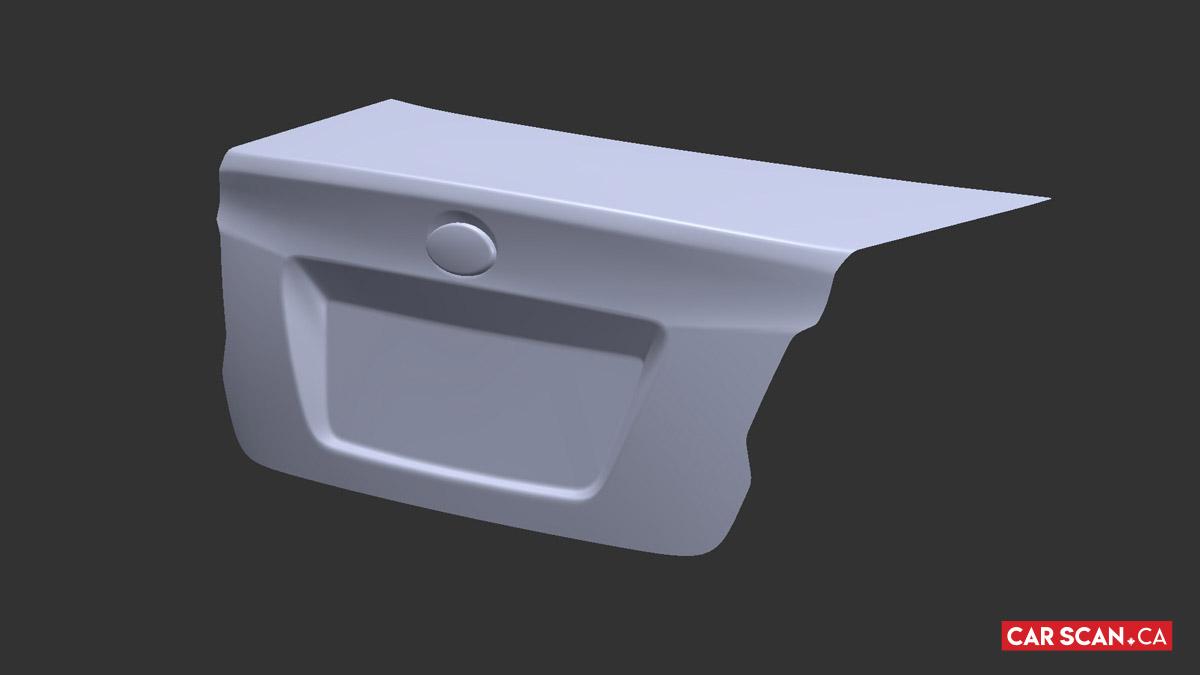

Reverse-Engineering, sometimes called re-surfacing, is the practice of taking laser scanned 3D data and tracing over it to create a copy of the geometry in usable formats. All laser scanners capture data in “polymesh” format. Polymesh files are highly accurate and often contain millions of points, but are not compatible with most manufacturing and prototyping process and programming. Reverse-Engineering traces these files into “NURBS” format; a format which utilizes lines, arcs, edges, circles, curves, and surfaces, all formulaically and mathematically defined. NURBS files are universal and can be read and write by all major CAD software.

How Does It Apply To Vehicle Projects?

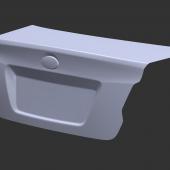

Reverse-Engineering is a crucial phase for automotive projects because high quality, accurately drawn files lead to better fitment for exterior accessories and more precise tolerances for performance components. Our modeling team ensures every detail is re-surfaced faithfully to the original geometry as much as possible, providing you with reliable and assured data.

Technical Information:

| 3D NURBS Formats and Outputs: | .STEP (STP), .IGES (IGS) |

| 2D Vector Formats and Outputs: | .DXF, .DWG, .PDF |

| Other 2D Formats: | Sheet Metal Feature, Dimensioned Drawings |

You Need Reverse-Engineering If You:

- Need highly accurate and usable data, especially for prototyping or manufacturing

- Need components to follow specific complex contours

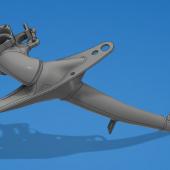

- Need the vehicle or parts in a specific format for CFD simulation or FEA analysis

- Make modifications, repairs, or iterations on an existing object

- Are looking to build a system of components, such as engine or suspension assemblies

What If I Need To Make Changes?

In some cases, certain design changes may be required, these may include: mechanical or performance improvement, aesthetic changes, or repairs. Reverse-Engineering is the optimal phase to include the changes - our team can take notes of the requests and implement the adjustments during the re-surfacing stage for efficiency. Examples of specific change requests: adjusting bosses or ribs, changing dimensions of diameters and radius, repairing imperfections (dents, rust damages, etc.).

Methods of Reverse-Engineering

Reverse-Engineering can be performed through various methods; ranging from fully automated processes to manual techniques. There are benefits and disadvantages to every method and our design team can consult and advise you on the most suitable and appropriate method for the project. Automated methods often generate unexpected, inconsistent, messy, and inaccurate results. Whereas manual processes provide clean, calculated, defined geometry, resulting in higher quality surfaces and solids. Our team is fully proficient in performing Reverse-Engineering in numerous formats and degrees of depth.