3D Laser Scanning

3D laser scanning is the practice of utilizing specialized equipment to extract physical geometry to become digital models and data. Within the virtual space, the highly accurate data is a representation of the real object, containing all the surfaces, edges, shapes, and dimensions. The scanner creates calculations at a rapid rate through its series of cameras and lasers, and triangulation algorithms.

How Does It Apply To Vehicle Projects?

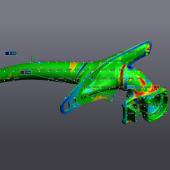

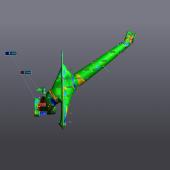

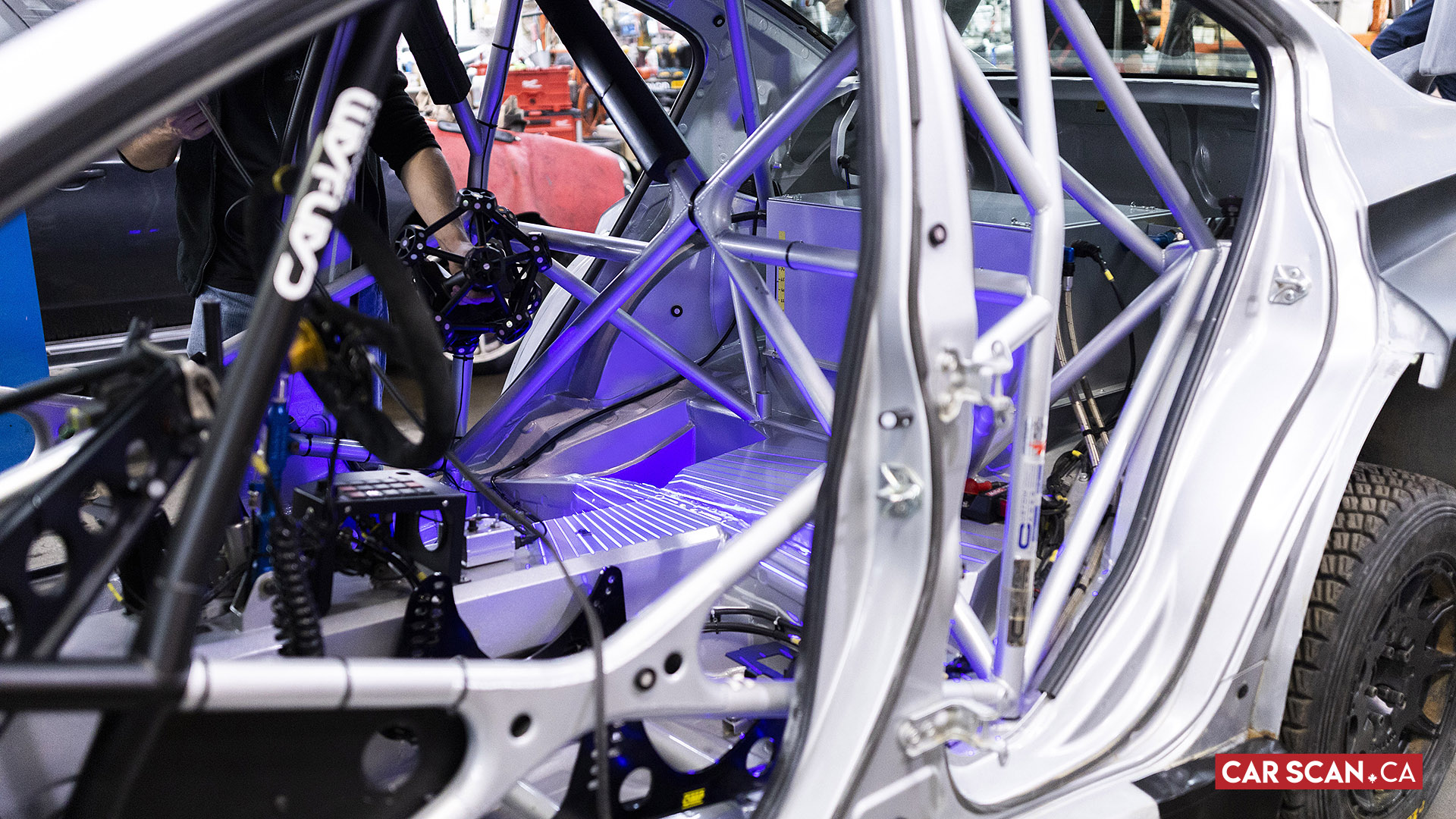

Vehicles contain multitude of complex surfaces on the outer body and detailed geometry on the chassis frame. These shapes and dimensions are often difficult to extract by manual, traditional methods such as digital calipers and probes. Compound curves contain precise transitions, and templates are time-consuming to create. Engineering details require precise measurements that may be difficult to reach or verify by hand.

Automotive Laser Scanning is a highly efficient solution to create an accurate representation in digitized CAD. With the use of scanning, all the complex curves and geometry are captured instantly, allowing designers, engineers, fabricators and builders to work digitally and perform tasks that would be otherwise difficult, or in some cases impossible, to do. Laser Scanning is often referred to the first step in any vehicular project - once the data is complete, all inspection, verification, modification and customization can be performed on the file - greatly streamlining workflows and reduce development time.

Our Equipment

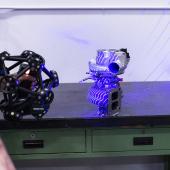

We only use industrial-grade scanners for our services; all our metrology equipment is designed, engineered, and manufactured in Canada. Our flagship scanner utilizes powerful blue laser technology, is ISO 17025 Accredited for 25 micron accuracy (in most cases, better), and target stickers are not required for its contact-free scanning. Furthermore, the tracker system retains extremely high volumetric accuracy even for large objects. Another innovative feature of our blue laser scanner is the ability to scan dark, glossy surfaces such as gloss black, to mirror-like, chrome finishes without any issues and without the need for powder coatings. This helps improve part precision and also reduce scanning time.

All our scanners are completely portable and transportable; allowing us to scan on-site at your location for convenience. Additionally, the scanner systems offer us the flexibility of scanning objects of almost any size (extra-small to extra-large), with the freedom to move the scanner into nearly any angle and area. This results in being able to scan surfaces that are normally difficult to capture, such as the inside of vehicles or in and around objects, such as engine bays.

Technical Information:

| Resolution (max): | 0.025mm (0.0009in) |

| Accuracy - ISO 17025 Accredited: | 0.025mm (0.0009in) |

| Probing - ISO 17025 Accredited: | 0.025mm (0.0009in) |

| Output Formats*: | .STL, .OBJ, .DAE, .FBX, .TXT |

*Other formats available, please see Reverse-Engineering

Applications - You Need Automotive Laser Scanning If You:

- Need dimensions and measurements from precise mounting points

- Need to verify spacing and clearance for new component installation

- Need to replicate or extract OEM fittings (i.e. snap-fit clips)

- Want a virtual copy of the chassis for digital design and engineering (i.e. rollcage)

- Want to take an existing hand-made model (i.e. clay model) and bring it to fabrication

- Are creating products that require precise fitment against complex curves (i.e. body kits)

- Are looking to replicate an existing part with non-contact methods (i.e. restoration)

- Are looking to create 2D templates from 3D data (i.e. for vinyl cut, wraps, and templates)

- Need a digital copy of a physical car and components for archival purposes (i.e. classics)

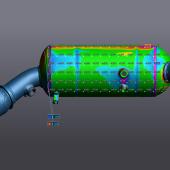

- Need to perform inspection on mechanical components or molds

How Does Laser Scanning Differ from Other Types Of 3D Scanning?

Unlike “photogrammetry” or “white light scanning”, the process of laser scanning does not rely on emitted patterns or geometrical recognition as references to calculate measurements. Laser Scanning utilizes triangulation calculation methods through its series of cameras and lasers. This process extracts precise surface measurements without relying on software stitching – resulting in highly accurate data.